| HOME | CUSTOM WORK | FINE, HANDMADE ARTS & CRAFTS FURNITURE ...SINCE 1985 |

LINKS | |||||

| ABOUT US | SHOP TOUR | CONTACT US | ||||||

| YOUTH FURNITURE | MISSION FURNITURE | |||||||

| FEEDBACK CUSTOMERS' COMMENTS |

||||||||

| Beds Case Goods Chairs Coffee Tables End Tables Larger Tables Settles Stands | |||||||||||

|

|||||||||||

|

|||||||||||

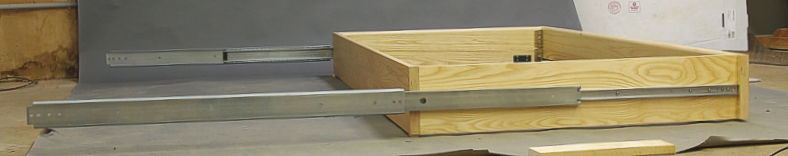

TIP……BEST IDEA…… IF YOU ARE BUILDING A BED, OR A BUILT IN WITH A BED ON TOP AND A TRUNDLE MECHANISM UNDERNEATH, We have evolved our Trundle Bed, and the trundle unit to the point that we can feel safe These units cannot be "stocked" by us. EACH UNIT SOLD HAS TO BE CUSTOM MADE TO YOUR EXACT SPACE REQUIREMENTS. Most usually, they are done in the Twin Bed format. However, we can build these units up to a size that will allow for a Full, or even a Queen sized Trundle. Never having built one that large, we are unsure of the application....BUT, we are confident that if you need a unit that size, we can build it. If you are building a bed or built in that will require a trundle unit, contact us as soon as possible in the planning stage so that the core requirements can be outlined. Obviously, there is a need for strength and stability where the trundle glides attach to the existing structure. We can offer guidelines that will make the fitting and use as easy as possible. We supply all necessary hardware to facilitate installation, and detailed, step-by-step instructions to guide you through the process.

The slat assembly is used to support the mattress or futon

We can make the trundle units almost any size…..up to Queen bed width and length.

The full-extension glides are rated at 500 lbs/pair.

We supply detailed instructions. All the components are numbered for easy assembly.

We could get away with one set of hardware….NOT our style, we double the hardware for a long, trouble free life.

The rollers contact the floor on about the last 12” of extension.

Multiple mounting screws on both the trundle, and the opposite side that mounts to your woodwork. It is easily asjusted.

LOOK AT HOW MUCH THE GLIDE EXTENDS PAST THE SIDE OF THE UNIT…..less than 1/8”.

Anywhere we can double the hardware….we do. Rock solid.

|

|||||||||||

4 Post Bed Mackintosh Keyhole Bed Trundle Bed Tulip Bed Glasgow Bed Liberty Bed |

|||||||||||